Shelf-life extension is a key question in the production, transportation and further sale of food products.

Modern automated horizontal or vertical autoclave will ensure the following:

- high-quality technology;

- wide range of products;

- free recipe generation by the process control operator;

- opportunity for further integration into your enterprise infrastructure.

We will help you turn complex into simple

EA Solutions LLC team will find optimal solutions for your enterprise.

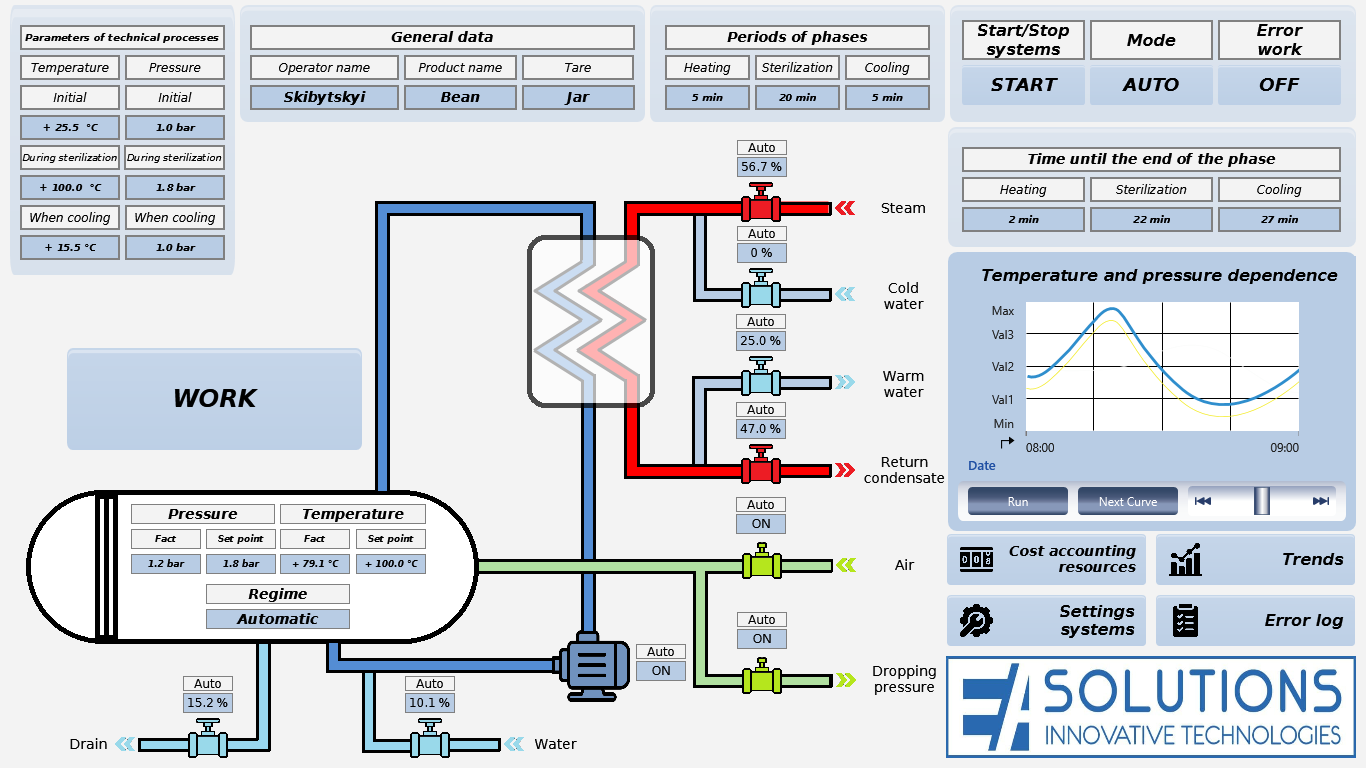

A block diagram shows major components of the autoclave control system.

Operate the technology through the single interface locally or remotely, from your smartphone, tablet or notebook.

Combine technological processes of your enterprise for the preparation and manufacture of products into the single interface.

Receive loss and profit reports to simplify calculation of your product costs.

Enhance your capacities through the automated transfer of data on the product amount and condition to the database or online store.

Transform technological process into the single digital interface at each stage

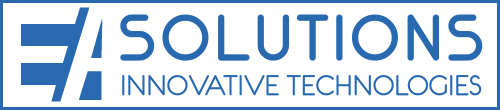

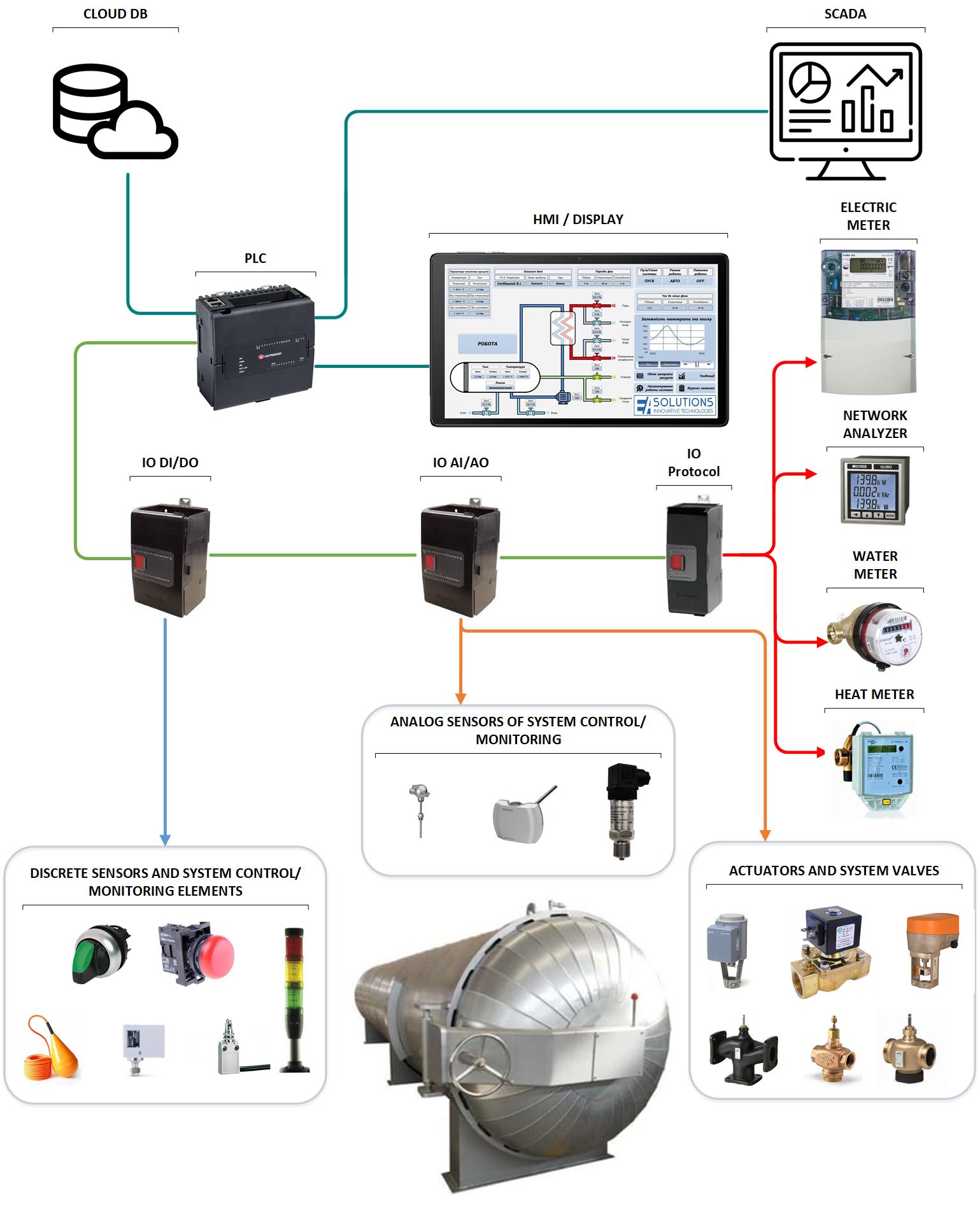

Control basic parameters on the main screen of autoclave:

- Time of heating, sterilization and cooling;

- Temperature and pressure of a separate process;

- Trends of a process.

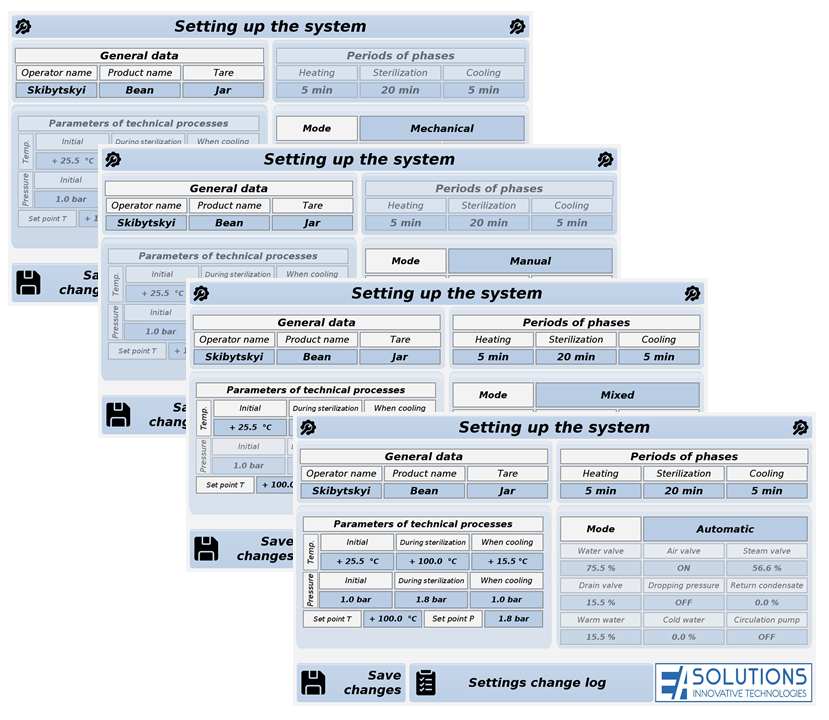

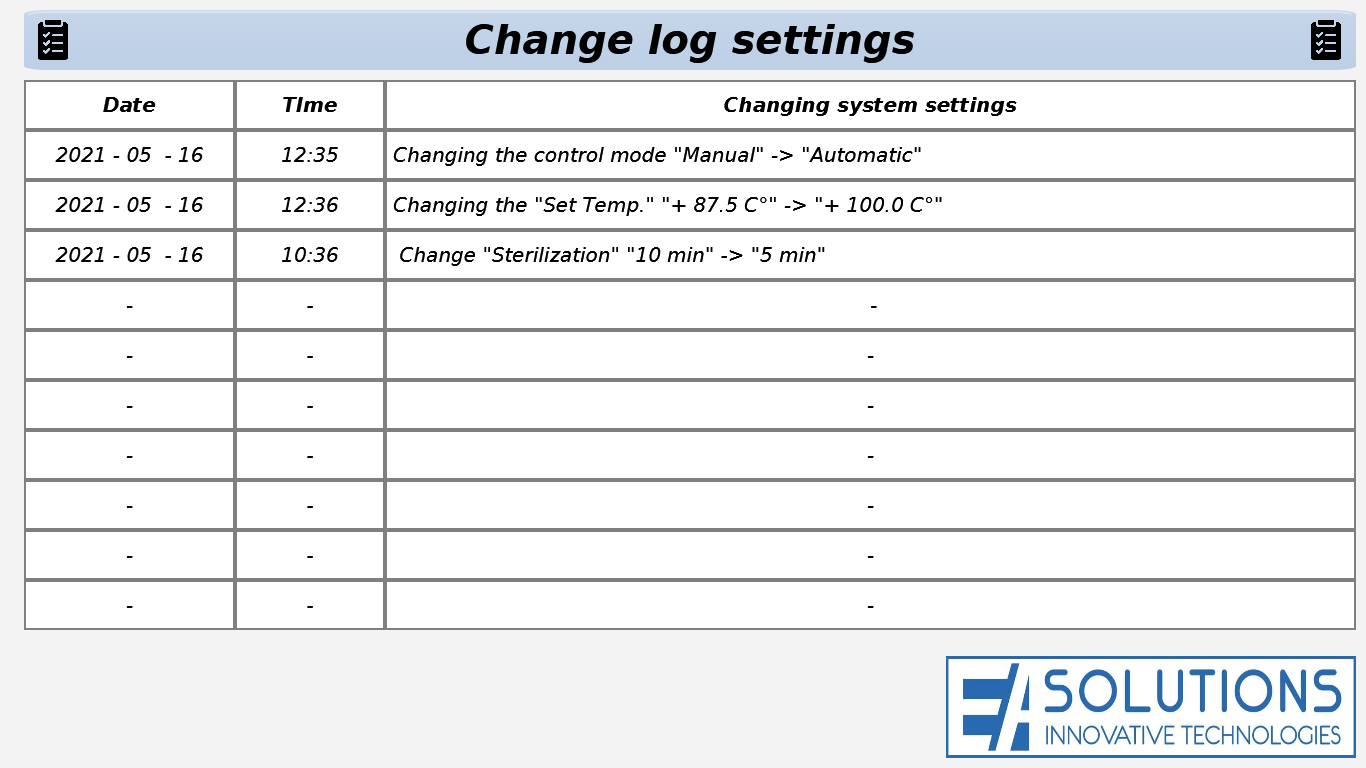

Change the recipe and the product, operate the system through the menu “Settings”, “Charts” and “Error Log”.

Constant analysis and accurate reporting improves the product and ensures compliance with manufacturing conditions

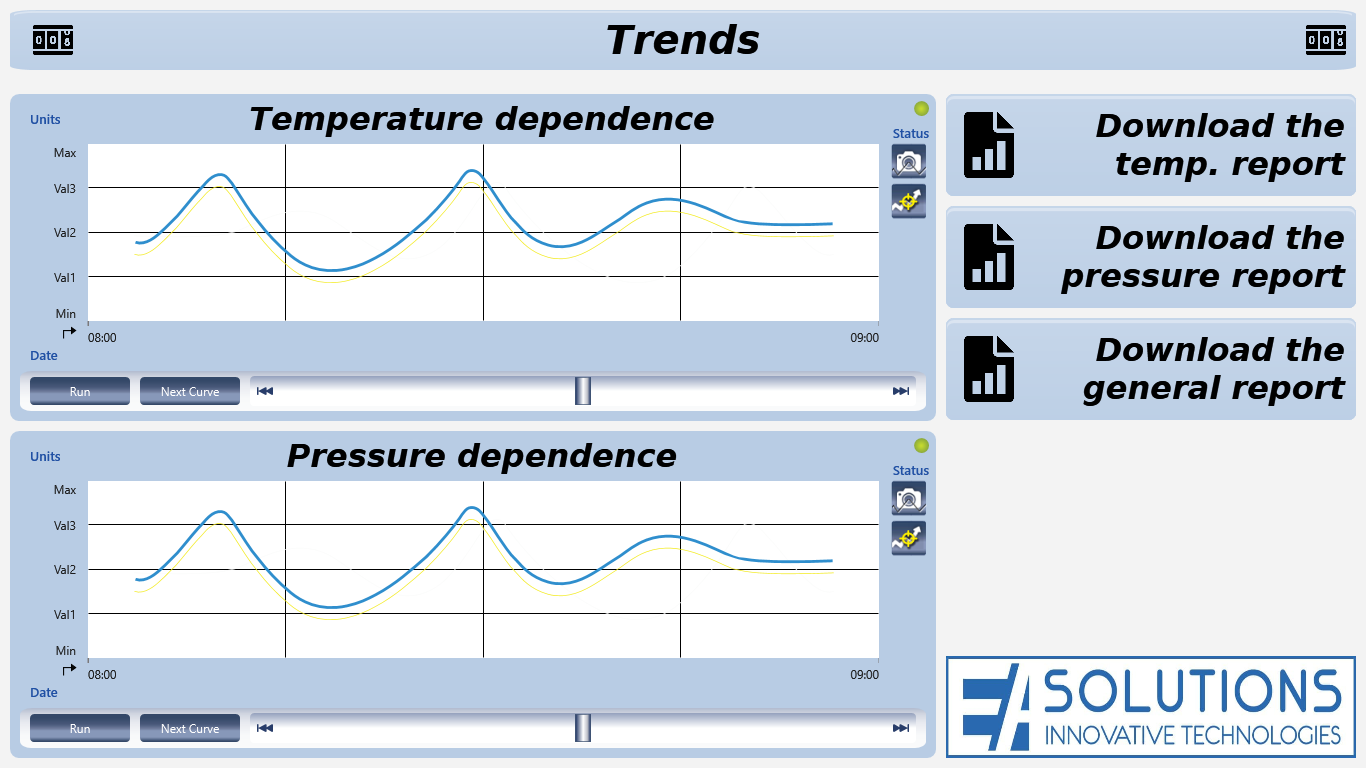

Press the button “Charts” on the main screen.

Review trends in real time and download the reports.

The data analysis will allow to track the system behaviour and the product itself under different conditions as well as gain experience working with certain products.

Get best results today

- Order a project on a turnkey basis with the transparent services and reliable equipment.

- Get 100% result due to the flexibility in system settings.

- Analyse and improve operation algorithms of your enterprise using logs and trends.

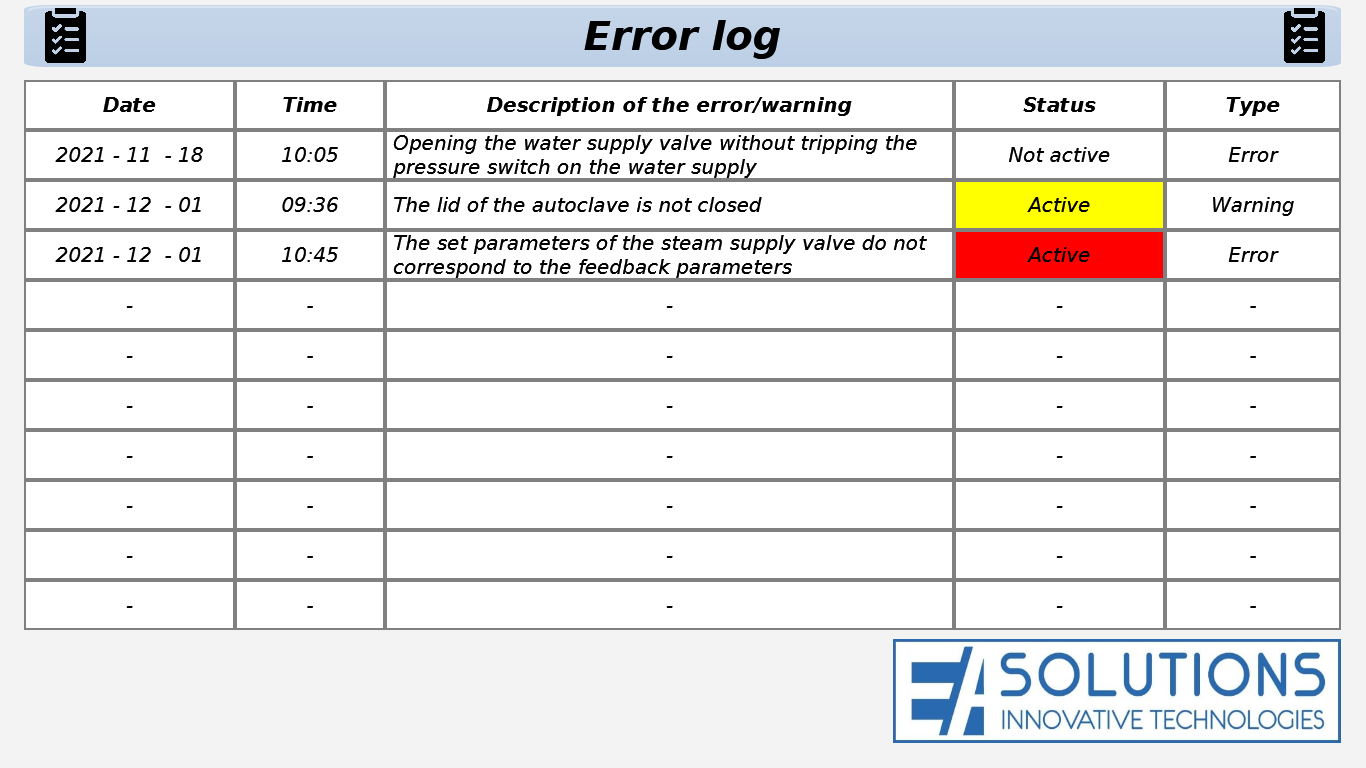

- Respond to emergency SMS messages in time.

- Operate the system anywhere and anytime with IOS, Android, Windows.

- Facilitate the reporting on the product condition and its amount, the state of equipment and maintenance needs; allow to do it automatically.